Kanda, a small town encircled by mountains on Japan’s southeast coast, is hundreds of miles from any major centers of business or politics. But recently, the only thing on its residents’ minds is President Trump.

In restaurants and bars and around Kanda’s small city office, people chatter nervously about the 25 percent tariffs he declared on car imports to the United States.

The reason for the anxiety is impossible to miss: The town’s lifeblood is a sprawling car factory owned by Japan’s Nissan Motor.

On a plot of land two-thirds the size of Central Park, more than 4,000 Nissan line workers produce hundreds of thousands of vehicles each year. Half of them are sold in the United States.

“We don’t really know what to make of the tariffs out here,” said Hironori Beppu, a councilor at Kanda’s chamber of commerce. “Without Nissan, Kanda’s financial situation would become really severe,” Mr. Beppu said.

Many things remain unclear about Mr. Trump’s automobile tariffs, which took effect on Thursday. Most important, how long will they stay in place? Or will the Trump administration be willing to negotiate?

Kanda, a town of around 38,000 on Japan’s southern island of Kyushu, could prove to be a preview of what plays out in similar export-oriented towns across the world if the tariffs are kept in place.

Since Mr. Trump’s announcement of the auto tariffs on March 26, Nissan has been considering transferring part of its domestic production of the Rogue, one of the models it produces in Kanda, to the United States, according to two people with knowledge of the matter who spoke on the condition of anonymity in discussing internal plans.

Any big production shift could prompt job reductions at the Kanda factory, causing economic pain to the town and potentially affecting Japan’s broader industrial landscape if replicated by other car companies. Some economists predict that the U.S. auto tariffs could as much as halve Japan’s economic growth this year.

Nissan’s manufacturing site in Kanda resembles a small town, stretching across more than 500 acres, with restaurants, traffic lights and manicured lawns. There are about 10,000 people working at the complex, counting logistics personnel and workers at companies that supply parts to Nissan.

At the site, buildings housing car-production lines connect directly to a port area, where hundreds of rows of vehicles fitted with left-hand-drive steering wheels sit in the sun, waiting to be shipped overseas. A colossal blue and white shipping tanker marked “Panama,” sat in the water nearby one day last week.

In Kanda, where Nissan first opened a factory 50 years ago, the economics of exporting cars long made sense.

The Rogue sport utility vehicle that Nissan makes in Kanda and sells in the United States is also produced in America. But Kanda built up efficiencies, and even factoring in the previous tariff of 2.5 percent and the expense of shipping the vehicles, it was less costly to export Rogues from Japan.

With a 25 percent tariff in place, workers at the factory say they don’t know what the calculus is anymore. Nissan did not respond to a request for comment.

The town of Kanda grew in tandem with Nissan since the automaker opened a plant in 1975. During a global expansion in the 1990s, Nissan built a second factory, making Kanda the company’s biggest domestic production zone.

Most areas outside major cities in Japan are rapidly aging. Kanda stood out as one of the few towns with a steadily growing population. City officials speak proudly of Kanda’s place as one of just a few dozen municipalities in country that don’t rely on subsidies from the national government.

“That’s thanks to Nissan,” said Kazuyuki Taguchi, head of Kanda’s department of transportation and commerce. “Our town is our car industry,” he said. “That’s why we’re trying to figure out whether tariffs are short-term, or long-term, and what kind of impact they may have.”

That is the question for everyone from Nissan leaders to Japan’s top officials.

In response to the U.S. auto tariffs, the prime minister, Shigeru Ishiba, said last week that Japan plans to set up about 1,000 offices nationwide that would investigate the taxes’ impact on domestic industries.

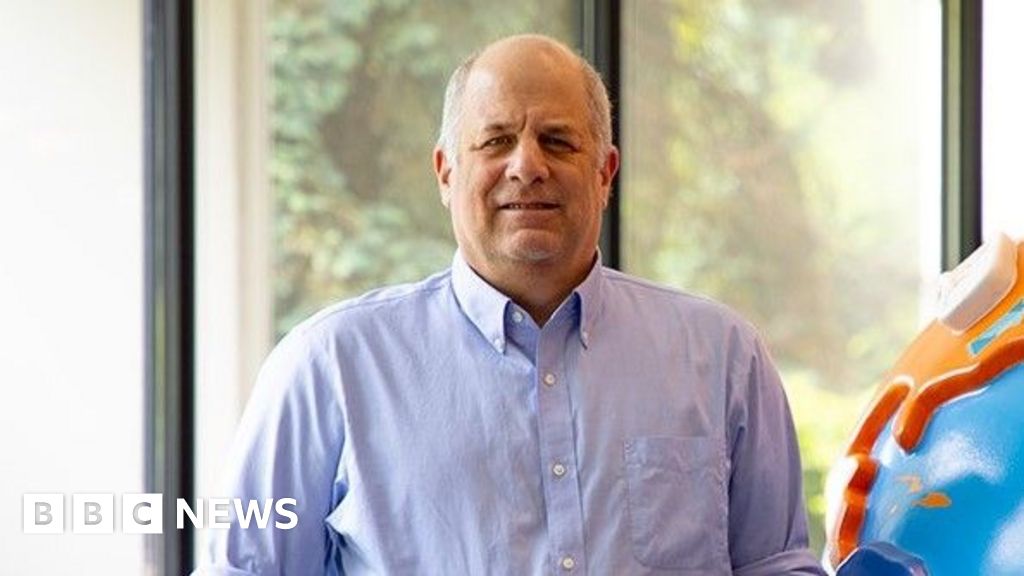

Ivan Espinosa, Nissan’s recently appointed chief executive said at an event last month that Nissan was trying to devise plans in advance for different tariff scenarios but that it was struggling with the lack of clarity.

The U.S. tariffs come as Nissan was already restructuring its global operations.

In November, after posting a 90 percent six-month drop in operating profit, Nissan said it planned to slash 9,000 jobs and reduce its global production capacity by around 20 percent. Around that time, Nissan began looking at a potential merger with Honda Motor, but the talks fell apart a few months later.

People at Nissan say it is working on a restructuring plan that will probably make deeper cuts.

Nissan had intended to scale back some production in the United States as well as in other regions. But last week, the company said it now planned to maintain previous levels of American production, including at its plant in Smyrna, Tenn., where it produces the Rogue S.U.V.

The goal, Nissan said, was to “keep more localized volume in the U.S. that is free of the new auto tariffs.” Production of U.S. models in Mexico and Japan will “continue based on market needs,” it said.

For now, when it comes to moving production out of Japan, car companies are unlikely to take big knee-jerk actions in response to tariffs, said Takaki Nakanishi, the head of the automotive consulting firm Nakanishi Research Institute in Tokyo. Rather, they will sell off the roughly one or two months’ worth of inventory they have in the United States and “wait and see,” he said.

If the tariffs last six months or a year, “companies can more or less swallow this impact,” Mr. Nakanishi said. “If they last four years, this will require structural changes.”

On a recent Sunday evening in Kanda, several Nissan workers gathered at a small bar near the train station, drinking and singing karaoke. Chieko Isshiki, 62, the bar’s owner, said Nissan employees had been her primary clientele for the past two decades.

Behind the counter, sipping a drink and occasionally puffing on an electronic cigarette, Ms. Isshiki said her customers read about the tariffs in the news. “Even those of us whose lives are supported indirectly by the Nissan factory are feeling the unease,” she said.

One of the Nissan employees at Ms. Isshiki’s bar that night was a 39-year-old line worker with bleached blonde hair who had relocated from Nagasaki to work at the Kanda plant. Now a father of two, he lives near the plant and mostly builds vans on its production lines.

“The tariffs are a concern, but I feel like Nissan will do its best to protect its employees in Japan,” he said, asking that his name not be used. “Anyway, for us on the floor, all we can do is listen to the directions from the top and keep making cars.”

Source link